The Challenge

Buffalo City Court is a 10-story building located in downtown Buffalo, New York, approximately 10 miles from Lake Erie. Energy performance contractor Wendel Energy Services was engaged to replace the existing 200-ton and 400-ton chillers and associated 600-ton three-cell cooling tower with new, highly efficient equipment. The application is HVAC comfort cooling for seasonal use (May to October). The engineer had calculated the peak load at around 500 tons, which would occur during about 5% of the cooling season.

The cooling tower had to meet cooling capacity and had the added challenge to fit the same footprint as the old tower, which was closely surrounded by walls on three sides.

The Solution

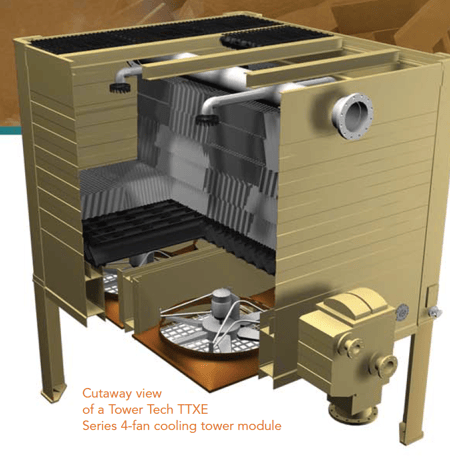

A Tower Tech open loop, eight-fan cooling tower was selected to satisfy the design conditions and space limitation. Although the capital expenditure was around 25% more than a competing, the forward-thinking project team also calculated the conventional-design tower, the installation and operational expenses. The projected energy, maintenance and chemical treatment savings were exceptional, but what really closed the deal with the installation savings. The equipment installer explained that the Tower Tech tower would arrive as a single cell with the mounting of the support legs and external sump taking place on the ground, prior to lifting the tower to the rooftop.

To keep the same cooling functionality on days where the wet bulb temperature may exceed the 75°F design when the building load is still 400 tons or less, a conventional tower would require a second, 400-ton chiller and cooling tower to share the load and get the condenser water temperature back in line. Because the Tower Tech cooling tower uses all of the fill media surface area all of the time due to the turndown capability of the Rotary Spray Nozzle, fan speeds could be increased gradually until the condenser water set-point is reached, thereby keeping the single chiller satisfied and the second chiller turned off.

Tower Tech was also able to meet the principal goals of reducing system piping, using a single VFD to drive all eight fans simultaneously and communicating with the Building Automation System (BAS). And because Tower Tech modular cooling towers use multiple, smaller fans on a VFD, the tower can continue to provide some cooling even if a fan goes offline and notifies the BAS that maintenance is required.

The Result

The year after the courthouse tower went into operation, Buffalo experienced one of the hottest summers on record. The design wet bulb temperature of 75°F was exceeded on at least 20 days, yet the second chiller was never needed. The Tower Tech tower was up to the record-breaking challenge.

Cooling Tower Specifications:

- Open circuit modular cooling tower

- 6’ high sub-structure

- Rotary Spray Nozzles™ (3:1 turndown capability with 6’ x 6’ Square Spray Pattern)

- U.S. electrical motors with fan motor control panel and temperature controller

- Six direct-drive fans

- Individual rotary disconnects

- Stainless steel fan motor support

Cooling Tower Design Conditions:

- Flow rate (GPM): 800 min/2,400 max

- Entering water temperature (HWT): 95°F

- Leaving water temperature (CWT): 85°F

- Entering wet bulb temperature (WBT): 75°F