Like any part of an HVAC system, cooling towers require certain maintenance to continue peak performance. The maintenance needed for a Tower Tech cooling tower is significantly lower than conventional towers, partly because of its nozzles. These variable-flow spray nozzles are essentially “self-cleaning,” reducing required maintenance – and saving businesses money.

Inefficiency Can Start at the First Stage of Cooling

Cooling towers pass chilled water over the tower’s fill media to cool the air for recirculation. This water is distributed by plastic nozzles, with an opening most often ranging from 1/8 inch to 2 inches, that spray water across the fill media, usually in a 360-degree circular pattern over the square fill media. When debris clogs the nozzle opening or minerals build up, water distributes unevenly, and cooling efficiency reduces – or stops.

Conventional tower nozzles generally require monthly maintenance to confirm that the nozzles are functioning properly and to clear clogs. Not only does this require significant time (and money) to unplug, clean and re-plug the maze of spray nozzles each month, but it also exposes maintenance personnel to safety hazards.

Tower Tech Nozzles Keep Water Moving with Less Maintenance

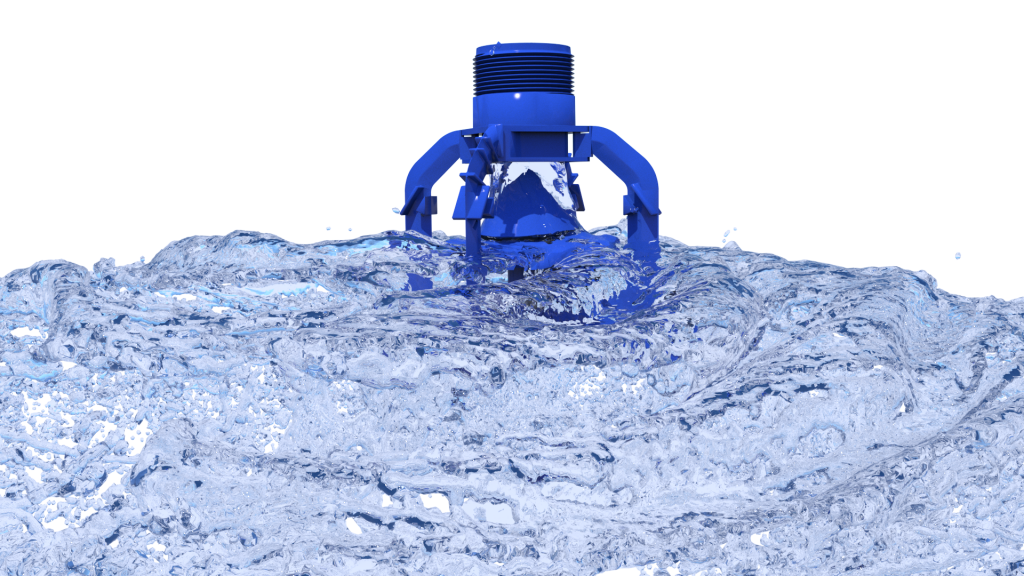

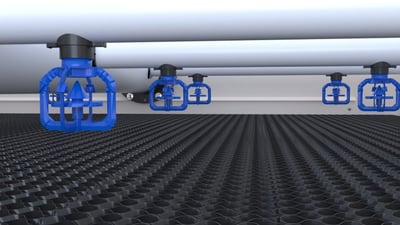

Standard on every Tower Tech cooling tower is a “spin-free” spray nozzle that delivers even fill coverage across a broad range of system flows. The two-inch (5.08 cm) nozzle throat/inlet and brisk rotating agitation action of the nozzle’s turbine clears debris that would clog conventional nozzles and require manual maintenance.

.jpg?width=400&height=225&name=Nozzles_Installed_Wet_02-768x432%20(1).jpg)

The nozzle orifice produces a square spray pattern that uniformly wets the entire fill media and reduces scaling on dryer areas of the fill. Unlike fixed-orifice spray nozzles, spin-free spray nozzles do not need to be near the design flow to provide needed coverage.

The combination of debris-clearing and better fill coverage maximizes Tower Tech towers’ cooling capacity and energy efficiency, even under partial load duties. And because these nozzles each can perform from 25 GPM to 75 GPM, they offer a three-to-one turn down from the maximum allowed flow rate. The variable flow capability saves fan energy usage requirements during off-peak-load requirements and helps the usable life and cleaning requirements of the fill media by constantly keeping it wetted. In effect, there is no “wet-dry-wet” cycle on the fill media that can accelerate deterioration. Requiring less operational pressure, these tower nozzles are virtually maintenance-free and are significantly more efficient.

Contact us today to discuss the difference a tower’s nozzle can make.