What We Do

In 1991, Tower Tech developed a radically different, modular cooling tower designed to significantly improve upon the conventional design philosophy that had dominated the cooling tower industry.

But the innovations were only just beginning.

Tower Tech Innovations

-

Pultruded FRP Towers

A major Tower Tech design innovation to use highly engineered Fiber-Reinforced Polymer (FRP) composite technology. This material eliminates the possibility of corrosion that is typical of galvanized towers and is much lighter. Working with Creative Composites Group, the largest structural FRP manufacturer in the USA, Tower Tech's pultruded FRP design is the strongest cooling tower on the market.

.jpg)

-

FireStrong™ and StormStrong®

Because FRP can be highly-engineered for strength as well as fire-retardancy, Tower Tech is the leader for facilities that require the strongest towers on the market. Tower Tech is the first factory-built FRP tower to garner FM Approvals for hurricane, missile, storm, seismic and fire.

-

Variable Flow Nozzles

Clogging is a primary deficiency of conventional nozzles, especially in dirty-water applications. To combat clogging, Tower Tech's nozzle design maintains hydraulically uniform water distribution at varying flow rates, achieves a low water profile by employing a lateral spray pattern, provides essentially clog-free operation by incorporating a turbine into the nozzle and maintains spray pattern size and near-constant pressure drop by use of an automatically adjusting flow-sensitive orifice. The nozzle requires less head pressure since the turbine in the nozzle is far more efficient than the conventional approach.

.jpg)

-

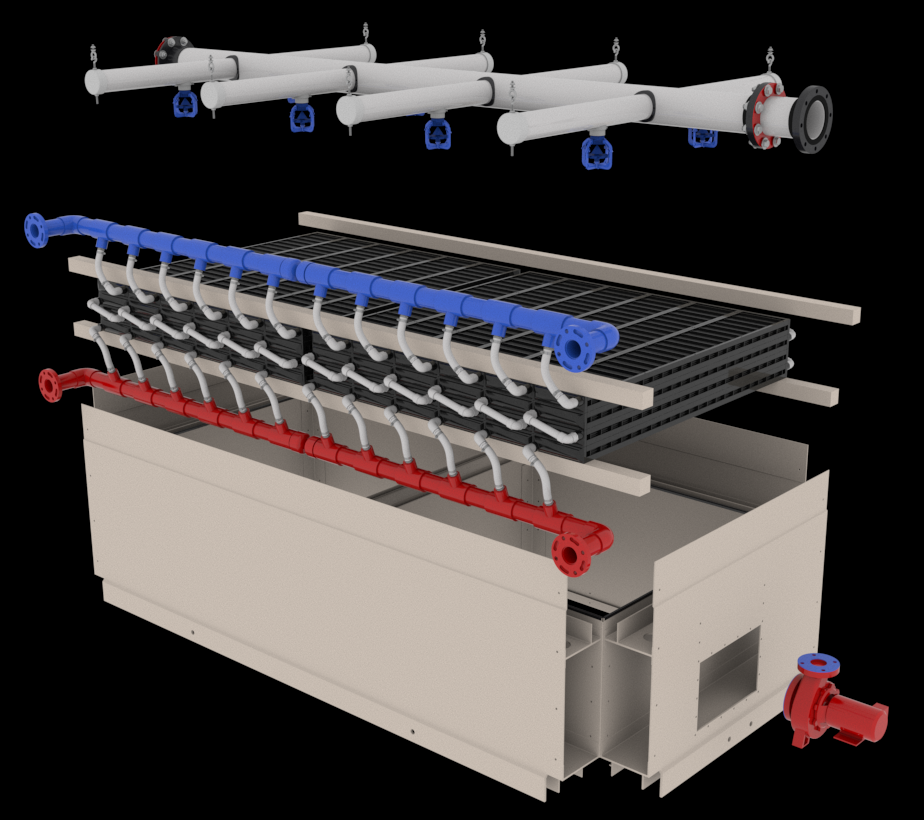

FlowThru™ Basin

Another design shortcoming of conventional cooling towers is their cold-water collection basins. These open basins tend to accumulate debris, are exposed to direct sunlight and contain regions of stagnant water. In combination, these can lead to excessive sediment build-up and increase the need for algaecides and biocides. Tower Tech invented a patented enclosed, elevated-basin design called the FlowThru Basin. Pump energy requirements are reduced, basin maintenance is virtually eliminated and algaecide is not required since the basin water is not exposed to sunlight. The self-cleaning nature of the Tower Tech FlowThru Basin eliminated the build-up of sludge, common in stagnant regions of most towers and avoid the growth of bacteria, such as Legionella.

-

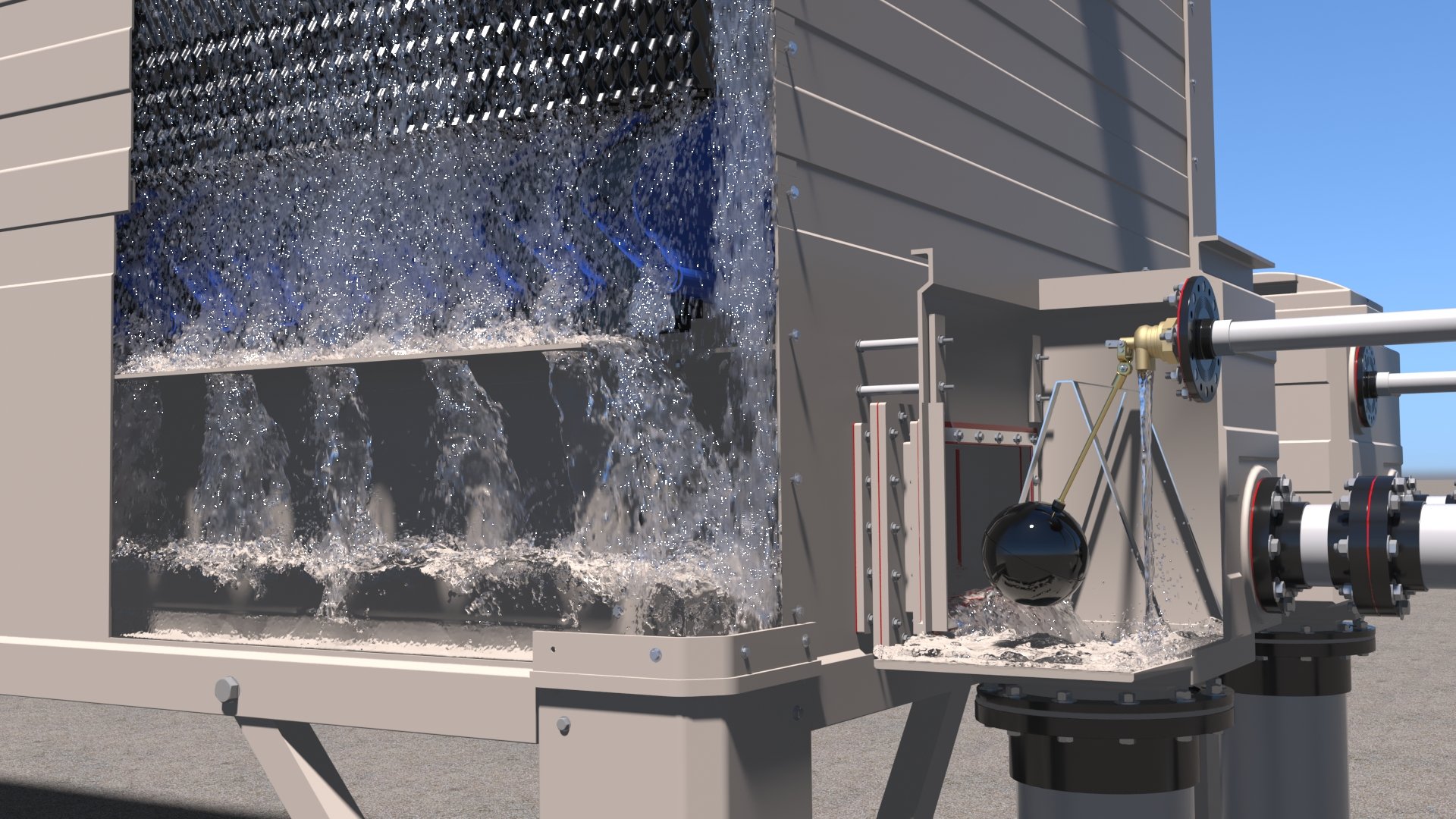

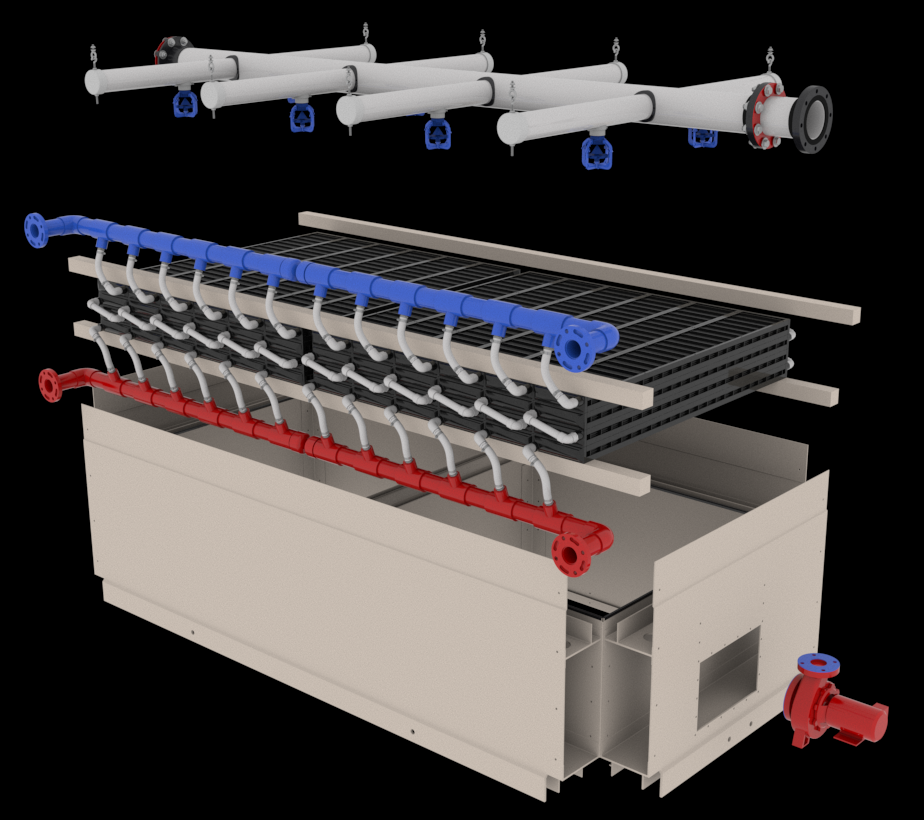

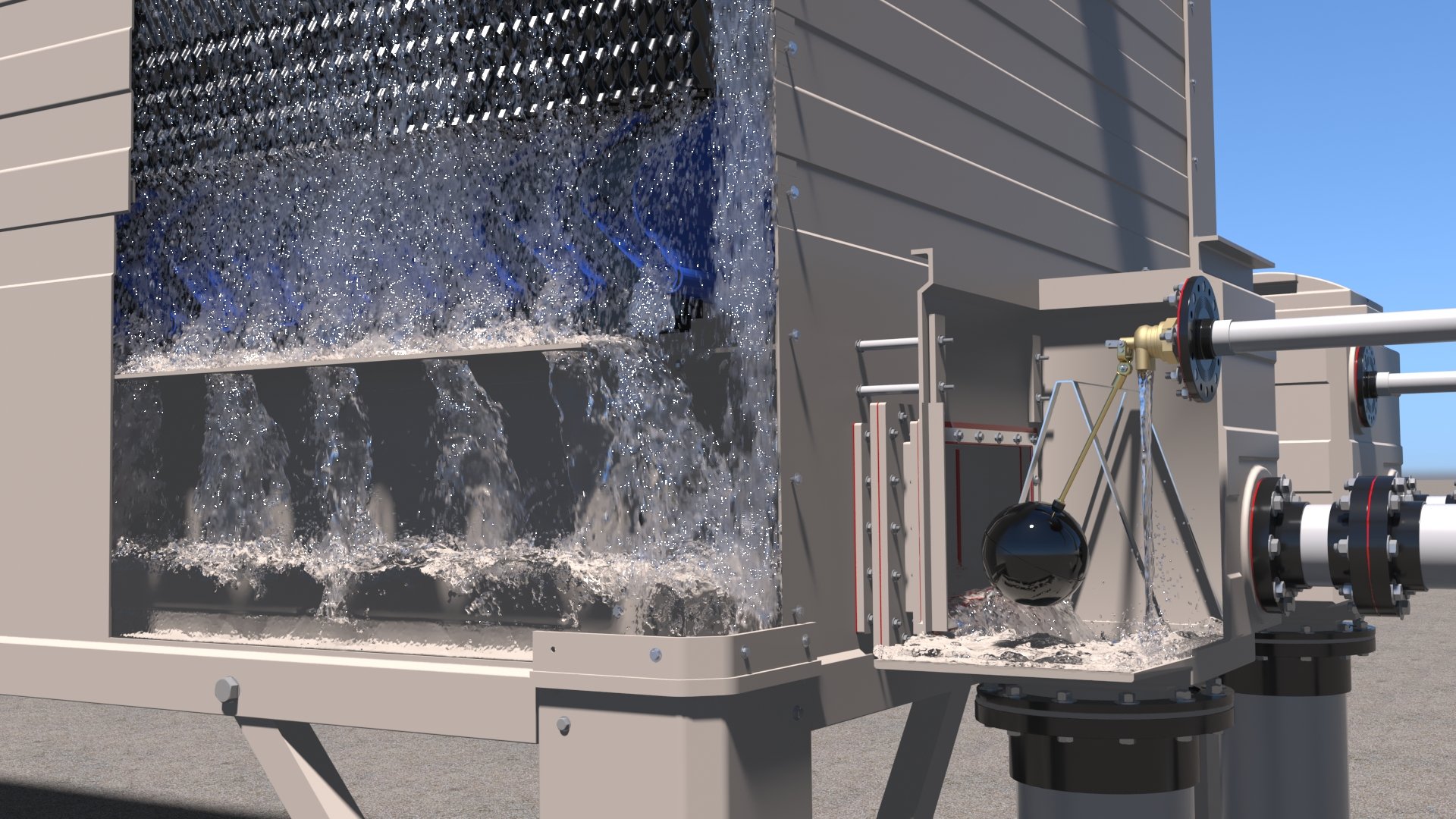

Water Collection System

The FlowThru Basin on the Tower Tech design was made possible by the invention of a system of water collection channels above the fans. These channels move the water laterally from the bottom of the fill to the enclosed FlowThru Basin while still allowing air into the fill. The installation of the Water Collection System creates a dry region under the tower, moving the fans away from the moist, hot air stream on the top of the tower while protecting the mechanical equipment from the natural elements. Placement of the tower mechanical equipment at ground level increased the longevity and maintainability of the equipment. Patents on the Water Collection System were awarded in the 1990s.

-

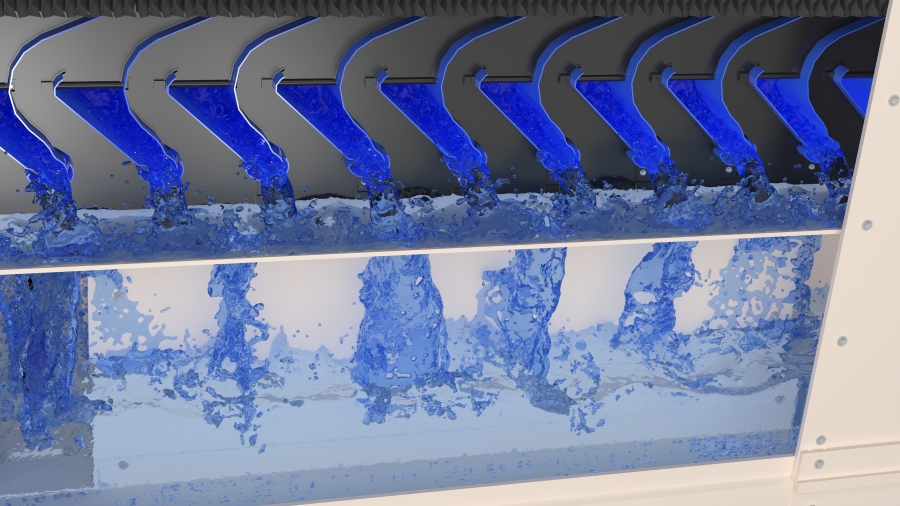

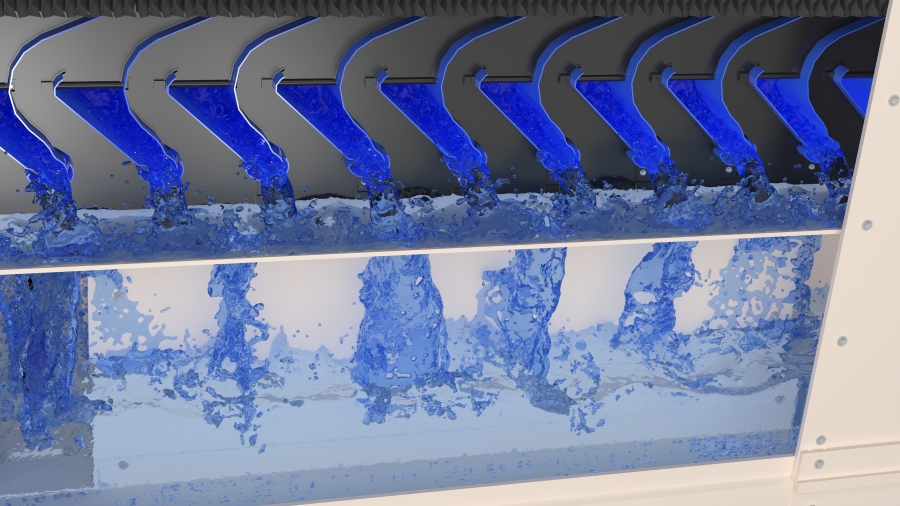

XchangeTech™ Fill Media

Our XchangeTech OEM fill media uses a unique waterfall technology that optimizes the heat exchange surface via materials design and engineered air/water patterning. The cross-corrugated PVC film is designed to operate under most thermal, process and water quality conditions while resisting biological and chemical degradation.

Pultruded FRP Towers

A major Tower Tech design innovation to use highly engineered Fiber-Reinforced Polymer (FRP) composite technology. This material eliminates the possibility of corrosion that is typical of galvanized towers and is much lighter. Working with Creative Composites Group, the largest structural FRP manufacturer in the USA, Tower Tech's pultruded FRP design is the strongest cooling tower on the market.

.jpg)

FireStrong™ and StormStrong®

Because FRP can be highly-engineered for strength as well as fire-retardancy, Tower Tech is the leader for facilities that require the strongest towers on the market. Tower Tech is the first factory-built FRP tower to garner FM Approvals for hurricane, missile, storm, seismic and fire.

Variable Flow Nozzles

Clogging is a primary deficiency of conventional nozzles, especially in dirty-water applications. To combat clogging, Tower Tech's nozzle design maintains hydraulically uniform water distribution at varying flow rates, achieves a low water profile by employing a lateral spray pattern, provides essentially clog-free operation by incorporating a turbine into the nozzle and maintains spray pattern size and near-constant pressure drop by use of an automatically adjusting flow-sensitive orifice. The nozzle requires less head pressure since the turbine in the nozzle is far more efficient than the conventional approach.

.jpg)

FlowThru™ Basin

Another design shortcoming of conventional cooling towers is their cold-water collection basins. These open basins tend to accumulate debris, are exposed to direct sunlight and contain regions of stagnant water. In combination, these can lead to excessive sediment build-up and increase the need for algaecides and biocides. Tower Tech invented a patented enclosed, elevated-basin design called the FlowThru Basin. Pump energy requirements are reduced, basin maintenance is virtually eliminated and algaecide is not required since the basin water is not exposed to sunlight. The self-cleaning nature of the Tower Tech FlowThru Basin eliminated the build-up of sludge, common in stagnant regions of most towers and avoid the growth of bacteria, such as Legionella.

Water Collection System

The FlowThru Basin on the Tower Tech design was made possible by the invention of a system of water collection channels above the fans. These channels move the water laterally from the bottom of the fill to the enclosed FlowThru Basin while still allowing air into the fill. The installation of the Water Collection System creates a dry region under the tower, moving the fans away from the moist, hot air stream on the top of the tower while protecting the mechanical equipment from the natural elements. Placement of the tower mechanical equipment at ground level increased the longevity and maintainability of the equipment. Patents on the Water Collection System were awarded in the 1990s.

XchangeTech™ Fill Media

Our XchangeTech OEM fill media uses a unique waterfall technology that optimizes the heat exchange surface via materials design and engineered air/water patterning. The cross-corrugated PVC film is designed to operate under most thermal, process and water quality conditions while resisting biological and chemical degradation.

Adding More Value

To add flexibility to the modular design, Tower Tech uses multiple, smaller fans instead of one large one. This builds in redundancy and reduces motor replacement costs. The performance of the new modular design was further optimized by the installation of low horsepower motors that were installed vertically (shaft down), and fans were direct-drive, which obviated the need for gear reducers, driveshafts, couplings or pulleys.

Tower Tech first earned Cooling Technology Institute (CTI) thermal performance certification in 1993 and has continuously renewed its annual CTI certification since then.

Tower Tech has also implemented Lean Enterprise principles company-wide. Most Tower Tech associates have attended several Lean Enterprise and Six Sigma workshops and earned Six Sigma Black Belts, Six Sigma Green Belts and other industry recognition.